Making RSO, or Rick Simpson Oil, a cannabis concentrate popularized by Rick Simpson for its purported medicinal benefits. It’s made by extracting cannabinoids, primarily THC, from cannabis plant material using a solvent. Below is a step-by-step guide to making RSO from start to finish. Note that this process involves flammable materials and should only be done in a well-ventilated area, following local laws and safety precautions. Always check the legality of cannabis and its derivatives in your area before attempting this.

Materials Needed:

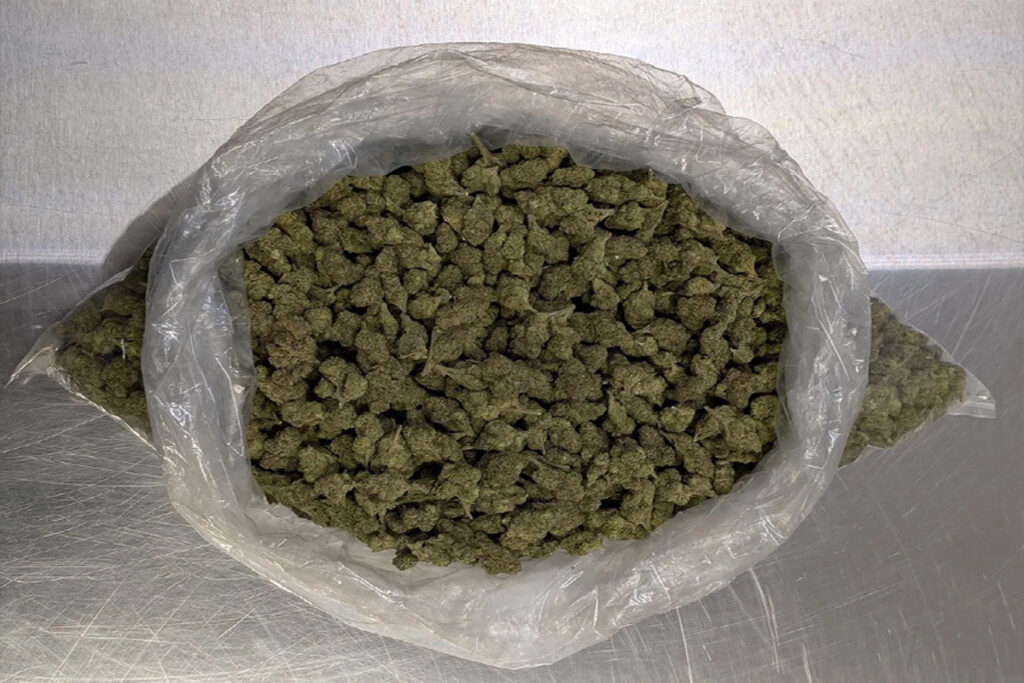

1. Cannabis: 1 pound (about 450 grams) of dried cannabis flower (indica strains are often preferred for RSO).

2. Solvent: 2 gallons (about 7.5 liters) of high-proof alcohol, such as 99% isopropyl alcohol or food-grade ethanol (avoid anything less than 90% purity).

Tools:

3. Two large buckets or containers (stainless steel or glass preferred).

- Wooden spoon or stick for stirring.

- Cheesecloth or fine mesh strainer.

- Rice cooker or double boiler (for evaporating solvent).

- Coffee filters (optional for finer straining).

- Syringes or glass jars (for storage).

4. Safety Gear: Gloves, safety goggles, and a well-ventilated workspace (preferably outdoors or with a fume hood). A fan can help disperse fumes.

5. Heat Source: For evaporating the solvent (rice cooker, double boiler, or hot plate).

Step-by-Step Process:

2. Wash with Solvent

- Pour enough solvent (e.g., isopropyl alcohol or ethanol) over the cannabis to fully submerge it—typically about half of your total solvent (1 gallon for 1 pound of cannabis).

- Stir the mixture gently with a wooden spoon or stick for about 3-5 minutes. This allows the solvent to dissolve the cannabinoids and terpenes from the plant material.

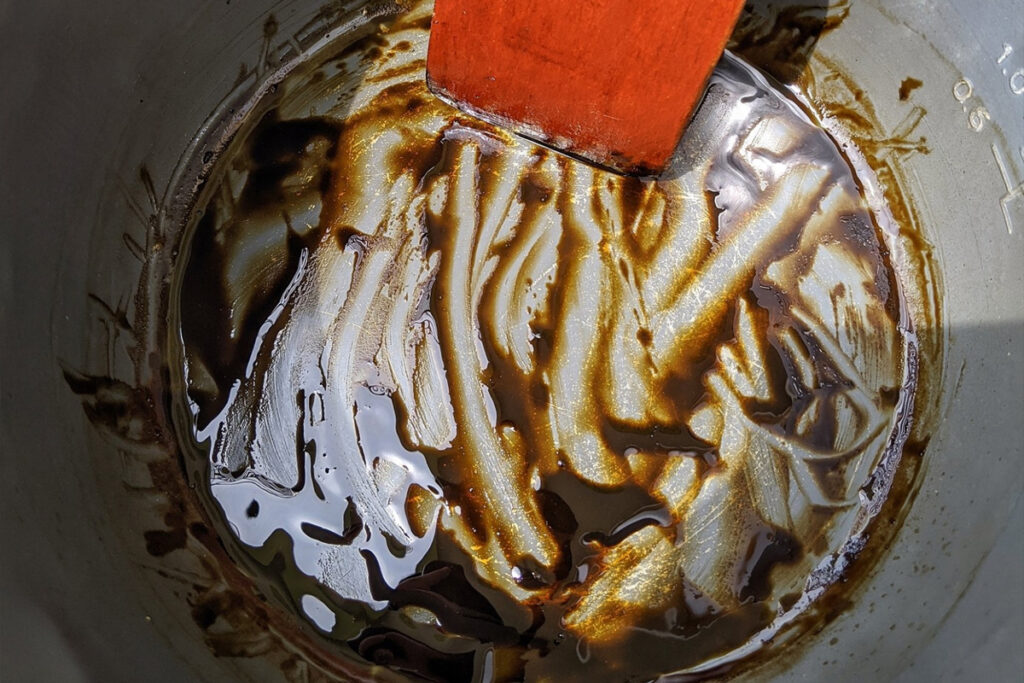

- After stirring, the solvent will turn a dark green or amber color as it extracts the compounds.

3. Strain the Liquid

- Place a cheesecloth or fine mesh strainer over your second bucket/container.

- Pour the cannabis-solvent mixture through the strainer to separate the liquid from the plant material. The liquid is your initial extract.

- Set the strained plant material aside (don’t discard it yet).

4. Second Wash (Optional but Recommended)

- Return the used cannabis material to the first bucket.

- Add the remaining solvent (another gallon or so) and stir again for 3-5 minutes. This second wash extracts any remaining cannabinoids.

- Strain this liquid into the second bucket, combining it with the first wash.

5. Filter (Optional)

- For a cleaner product, filter the combined liquid through a coffee filter into a clean container. This removes finer plant debris but takes longer.

6. Evaporate the Solvent

- Pour the filtered liquid into a rice cooker, double boiler, or heat-safe container. Use a low to medium heat setting (aim for 210-230°F or 100-110°C) to evaporate the solvent.

- Safety Note: Do this in a well-ventilated area, away from open flames or sparks, as alcohol vapors are highly flammable. A fan can help disperse fumes.

- Stir occasionally and monitor the process. As the solvent evaporates, the liquid will thicken into a tar-like consistency. This can take 1-3 hours depending on your setup and volume.

- The process is complete when no more solvent bubbles appear, and you’re left with a thick, dark oil.

7. Collect the RSO

- Once the solvent is fully evaporated, let the oil cool slightly.

- Use a spatula or spoon to scrape the RSO into a clean glass jar or load it into syringes for precise dosing. It should be sticky, dark, and viscous.

8. Store the RSO

- Store the finished RSO in an airtight container (syringes, glass jars, etc.) in a cool, dark place like a refrigerator. It can last for months if stored properly.

Yield and Potency

- From 1 pound of cannabis, you can expect 60-80 grams of RSO, depending on the strain’s potency (typically 20-25% THC content yields about 60-100 grams).

- The final product is highly concentrated, so it’s usually taken in small doses (e.g., the size of a grain of rice).

Tips and Warnings

- Decarboxylation: RSO is naturally decarboxylated during the evaporation process (heat converts THCA to THC), so you don’t need a separate decarb step unless you want to maximize potency beforehand.

- Quality: Use high-quality cannabis for better results. Trim or lower-grade material works but yields less potent oil.

- Purity: If using isopropyl alcohol, ensure all solvent evaporates fully—residual solvent can be harmful. Ethanol is food-safe and preferred by some.

- Legality: Cannabis laws vary widely. Ensure compliance with your local regulations.

That’s the full process! Let me know if you need clarification on any step.